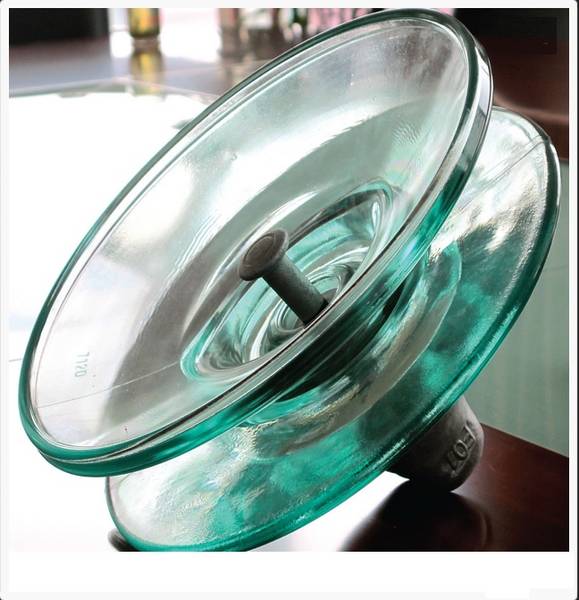

Design and construction of new glass suspensions

By James Mulvey; posted April 22, 2017

View Original: Click to zoom, then click to magnify (648 x 671) 136KB

|

Copied from the company's website, this has all the bits and pieces of information that I have been told over the years by a dozen different sources. All together and in one place, I thought it was worth sharing. The accompanying pictures can be viewed on the website, see link at the end of the text. james While there are hundreds of different porcelain insulator manufacturers scattered across the globe, those who produce toughened glass cap & pin discs number barely over a dozen. The reason for this discrepancy is certainly not a function of customer preference since glass and porcelain strings have traditionally had a roughly similar market share on overhead lines worldwide. Indeed, many countries, including France, Spain and Italy, have grids dominated by glass. China – with the world's largest power network – also sees an important role for glass strings on transmission lines and has the largest number of glass insulator plants of any country. INMR visits Sichuan YiBin Global Group – a glass insulator manufacturer based in central Sichuan Province. "The quality of an insulator is one of the keys to guaranteeing the reliability of a power system," observes SYGG's Deputy General Manager. "And achieving a consistently high quality depends on several factors including the right production technology, the latest equipment and skilled workers. "It was with these targets in mind," he adds, "that we decided to invest some RMB 280 million (circa USD 40 million) with the goal of establishing a world-class production line for glass insulator discs here in Chengdu. This investment was then supported by our Group's more than 20 years of relevant glass manufacturing experience." According to the Deputy GM, this process is ongoing as an additional RMB 40million was invested in R&D just over the past year to introduce new, very high strength insulator designs. Indeed, the technical manager reports that SYGG has several R&D projects underway, including a triple shed design as well as glass shells pre-coated in the factory with RTV silicone. "Our target," he states, "is to research all insulator designs up to 300 kN and 500 kV. With this range, we know we can cover the large majority of needs worldwide." The annual domestic market for glass insulators in China is estimated at about 20 million discs and reflects a fairly stable market in recent years. The annual domestic market for glass insulators in China is estimated at about 20 million discs and reflects a fairly stable market situation over the past several years. This volume is predominantly for AC, with about 7-8 percent for DC – a higher level than in the past. Moreover, because of the number of major DC projects now being planned by China's State Grid, the local market for DC insulators is expected to continue to grow rapidly Quality control staff use counters installed on each production line to record and track the rate of every type of defect identified during visual inspection. Production of glass insulators begins with the various raw materials, mainly quartz and sand, but which also include soda ash, calcite, feldspar and dolomite. The Director of the Raw Materials Workshop, explains that these materials are combined using a sophisticated computer-controlled batching system that guarantees a consistently precise final composition of the glass. These materials are mixed and fed into the furnace using two separate channels, each equipped with a powerful magnet to remove any metallic contaminants. About 1/3 of the mass fed into the furnace is cullet, i.e. previously formed glass discs that shattered subsequent to forming or were rejected downstream by quality control inspection and ground up. This cullet, which also includes any unused gobs of glass during mold changeovers, is a common feature of the industry since it contributes to the consistency of the glass manufacturing process. One of the key production parameters for insulators is ensuring homogeneity of the molten glass and this requires continuous stability of the furnace, which is designed to run at temperatures of up to 1000°C for years without need for a maintenance shutdown. A control room therefore monitors every aspect of the process until the molten glass gob – free of any bubbles, inclusions or impurities – is delivered by special feeders directly into preheated molds. These individual molds, placed on a rotating machine, receive the glass gob in a precise quantity and dictate the outer shape and dimensions of the shell. Internal geometry is then determined by devices inserted into the molten mass within the mold cavity. Pressing is critical because it not only imparts the final internal shape but also assures a uniform thickness throughout – a factor that will minimize any risk of shattering during the toughening process that follows. The importance of consistent thickness is especially evident whenever there is a need to change molds in order to produce an insulator of different design. Such changeovers may require a different volume of molten glass to be drawn from the furnace for each gob and breakage rate can rise slightly until the adjusted process stabilizes. After molding and spinning, the glass shells undergo the important toughening process. Here, surfaces are exposed to repeated cycles of rapid cooling from jets of compressed air while their inside continues to remain very hot. As shells move through the machine, their insides cool and shrink – a process that creates the desired compressive stresses at the surface. To achieve this effect, the glass must be very clean since the presence of even a tiny inclusion can lead to shattering. This toughening process is an important determinant of performance by ensuring the absence or propagation of cracks in the dielectric over the insulator's service life. After toughening, the glass shells are transferred through another thermal shock by immersion in cold water, as required in the standards. This entire process of repeated cycles of alternate heating and cooling helps eliminate the large majority of units containing inclusions or other defects since they will usually shatter under the rapid temperature change. Finally, there is a close visual inspection of each shell and any defective units are placed onto a conveyor for re-cycling as cullet. Those units that pass inspection basically complete and ready for assembly of fittings. SYGG's Director of Glass Shell Production reports that acceptance rates for glass shells in the Chengdu factory typically average around 90 percent – a level that he claims is probably higher than in the industry at large. He also explains that quality control staff use a series of counters installed on each production line to record and track the rate of every category of defect identified during visual inspection. "Production staff look at the relative incidence of every type of defect on a daily basis," he says "and discuss whether certain process parameters need to be adjusted, such as angle of burners, furnace temperature or gob feeding. Glass shells then move on to the next step in manufacturing, which consists of attachment of the metallic cap and pin to every unit. All hardware is first dipped in pitch to reduce risk of corrosion at key interfaces and also to provide a protective buffer between the glass and metallic surfaces that have different coefficients of expansion with temperature change. The fittings are then transported using an elaborate system of overhead conveyors to work stations, where production workers attach them to the glass shells using precise amounts of pre-mixed special cement. After assembly, there is curing in a hot water bath, whose temperature depends on the mechanical rating of the insulator. The last stage in production consists of testing, most of which is performed on production samples at SYGG's internal laboratory facilities. One test that is performed on every unit just after curing is for tensile mechanical strength, which, as per the standards, is done at 50% of the SML rating. According to the Testing Manager, SYGG has built facilities to conduct the majority of any testing either as per the standards or according to occasional special demands from customers. He notes that several power supply companies in India, Brazil and the United Kingdom have their own test requirements that are often different from or more stringent than those mandated by IEC. One example is RIV testing, which is usually done at 10 kV, 1MHz with a maximum permissible 34 dB. But, he notes, some customers in Brazil and the U.K. request testing at 30 kV, 1 MHz and 52 dB. Similarly, some Indian customers require insulation resistance measurements in the HV lab. Yet another example is the impact test, which he claims is almost no longer required today within IEC but which is nevertheless demanded and sometimes at an even higher level than specified in the standards. Yet another example of a special test requirement is asked for by the grid operator in the U.K. whereby a glass string is hung at angles of up to 30° inside a special tunnel and exposed to wind speeds of 20 m/second. If any noise is emitted, the string does not pass. While a relatively new player in an industry with a history going back more than 100 years, SYGG management claim they have already established their presence not only in China but in several overseas markets as well. In fact, Frances Wen, who heads the Export Division, reports that a substantial contract for a few million pieces was recently signed with a large Asian customer while new orders are coming from South America, Europe and most recently, the U.S. She also indicates that while about a third of sales went to export markets in 2011, the proportion this year will likely be closer to 50 percent. The Chinese market for transmission insulators has undergone a gradual shift in recent years. Whereas 5 years ago, it is estimated that glass accounted for some 40 percent of all insulator strings in service, with composite and porcelain types at about 35 and 25 percent respectively, composites have today basically exchanged the share with glass and, if anything, are only growing in importance. Recognizing this trend, the company's Deputy General Manager indicates that SYGG is now actively exploring composite insulators as an addition to their mainstay glass technology. "We are now developing our own line of composite insulators," he indicates, "and we hope to offer these in the short term." http://www.inmr.com/category/articles/insulators/ |