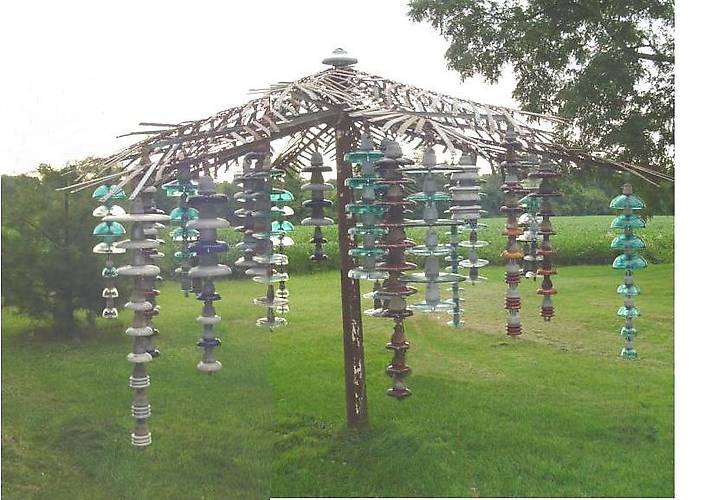

It was late in the year 2006 that Bob Scafe near Vancouver on the west coast, put out a request for help to transport a large number of suspension insulators to and from his trading partner Tracy Schaff in Maryland on the east coast. Bob named this "The Great Transcontential Suspension Insulator Exchange" . Aptly named as over 100 suspensions went coast to coast before it was over. I knew of a willing trucker, Indian Joe as he calls himself, who makes monthly runs from Toronto to Vancouver..As part of this exchange happened in the spring and part happened in the fall, I had over three dozen of them boat anchors hanging in my shed for the summer. I've never had any interest in suspensions, but sadly, they do grow on you. November came and I met Tracy at the show in Springfield where I finally unloaded these into the back of his truck . At the same time I picked up more strings from Tracy to be shipped out west over the coming winter to Bob . By the time spring had rolled around I had decided I needed my own collection. ......but I was determined to find a unique way to display them. That thought was easier said than done. Over the winter months I penciled out dozens of possible designs. Some held more suspensions than others. Other models could be added to as the collection grew. A few designs were mobile in that the suspensions could easily be rotated to produce a fresh 'view' . No more of the same old same old, everytime you looked out the window. Designs were discarded everytime I had a better idea. Finally, I focused on the idea of a suspension tree. Something reminiisent of a palm tree with strings of Spanish moss hanging from the branches. Over the next couple months I designed out what I wanted. Keeping it simple was the main criteria, which took much more thought. Each branch is independant of the others and can quickly and easily be removed for any reason. The final design is a compromise on many ideas, but the construction is so simple and cheap, easy and above all foolproof Because of the length of the branches, assembly was done outside on an eight foot table. Spring came and the warm weather finally arrived. The palm tree consists of 16 branches, on two levels. The lower level consists of eight branches; four are seven feet long, four are six feet long. The top level is eight branches five feet long. The actual branch part of the design is lengths of 3/8 heavy chain six inches longer than the T stake they are welded to. This had several benefits . The weight of the chain and the leaves produced an ever so slight sag; a visual effect picked up by the eye even if you are unaware of it. This is a more natural look . A useful feature of the chain was that in my design I used the links as a measure. I used every fourth link so each branch has leaves that are spaced the same. The leaves, well here is a good plug for dumpster diving. If it's free, I generally take it. I had gathered some 700 of the galvanized metal crossbraces that are used on poles to hold crossarms steady thinking that someday I might need them. And this was that day ! By using these as leaves I get two pieces out of each brace. Cut in varying lengths I placed the longer pieces to the tip of the branch, and the shorter piece that was cut off became a leaf closer to the trunk. I did not straighten any of the pieces, I used them as they were for a more natural look . For consistency I maintained the positioning of each piece of the brace so that the bolt hole was always the end of the leaf . In nature, all leaves are the same but all leaves are different. 18 braces to create 36 leaves were used on the longer branches . The short leaves come off the branch at almost 90 degrees. The longer leaves are at a much sharper angle. This meant each pair of leaves had to be cut at a different angle. To make this even more complicated, I raised the trunk end of the chain (branch) four inches off the table before welding the leaves to the chain. This was done so that the smaller leaves could hang down more than the longer leaves at the tip, which were welded to the chain to be almost flat. This had a dual purpose. Out at the tip of the branch, the longer leaves needed to cover more area, being flat they spread out wider. Where the branches converged near the trunk the shorter leaves had less area to cover. I could fit more leaves into the same space, giving a dense appearance, and also it gave a more overall 3-D effect to each branch and the whole tree in general. Each pair of leaves are welded to the top of an individual link. The chain was temporarily placed between two T stakes to keep the chain straight and prevent twisting while the leaves were being welded to it . The end link was welded to the tip of the T stake above the ring that been installed to hang one of the suspension strings. Because the leaves are galvanized, they will remain silvery for a long time. Since the chain is plain steel it will rust, providing the look of a wood branch with silver grey leaves. To hang the discs, 36 small clevis discs were sacrficed. The tounges being cut off and welded to the T stakes at the tip and at two ft. intervials. Strings of clevis type suspensions were hung directly from these rings, Ball type discs were hung using a Y connector. The trunk of the tree is a heavy metal light standard, with a slight taper towards the top. To attach the branches I made 16 evenly spaced slots in the top end just wide enough for the narrow edge of a chain link . The chain makes this adjustable, flexible, secure, easy to install, removable - in short, a perfect solution. The T stake is simply set inside a steel pocket created by welding a two inch section of slotted pipe to the trunk 12 inches directly below each slot. . The tip of the branch hangs lower than the base creating a 'low' spot which will cause the branch to return to this position after each wind. A string of suspensions is always in motion. So to reduce the overall stress on the structure, each branch has mobility. Because the chain is not welded, each pair of leaves can move independently. Because the T stake is not welded to the trunk, it can sway back and forth. The suspensions can wiggle on their own . My own preference was to mix suspensions together to make an assortment of designs. Reminiscent of Spanish moss hanging from a tree. The bigger discs to the top of a string. Darker colours also went to the top. In just a couple years I aquired over 170 different discs.. I have restricted this project to just ball/socket and clevis/tounge types. The sole exception is a single JD disc which is the crowning pinacle of the sculpture. I really don't know how to make 2,500 plus pounds of suspensions look attractive. I don't know if it is possible. But at least I don't have to keep moving them out of my way anymore. Great. Now that I can I see almost to the back of the shed I see 100 plus multiparts that I just have to do something with. (As published in Crown Jewels 2010) After this picture was taken over 100 more different suspensions were added bringing the total hung to 261 discs. In this picture the largest diameter ones shown are 15 inch and the smallest one is 3.5 inch |