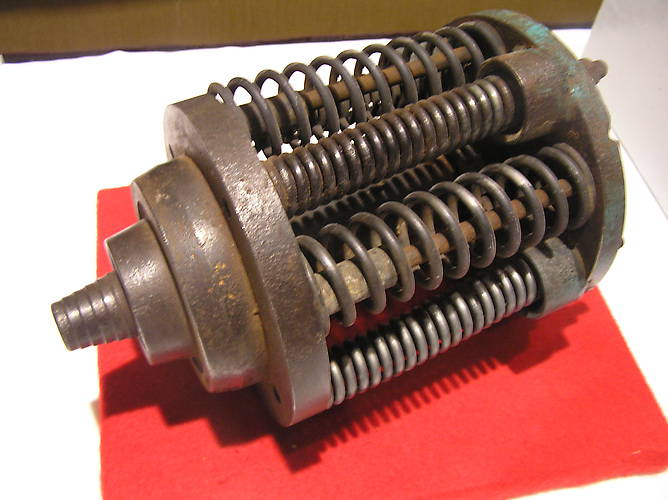

...the plunger assembly was pressed into the barely molten glass. How many pounds of clamping force did it take to overcome all these springs and press the plunger down? Probably no one living knows. Note these are not threads. The commemorative pieces were not true threads. Easier to mold & allows for easy identification that the piece was a commemorative! Mr. McLaughlin was not trying to deceive anyone by his products. This mold had springs that helped the mandrel pull out of the pinhole once the glass was frozen, then the two arms of the mold could be separated with the glass resting on the dome, upside down. It was then taken to an annealing lehr (good scrabble word) to cool for many hours. |